Corporate Profile

Greetings

In March 2012, RK ENGINEERING CO., LTD. was founded here in Hai Phong, which is Vietnam’s third largest city, as a manufacturer that can offer advanced manufacturing technology, quality control, and high-level cost effectiveness required by plant manufacturers inside and outside Vietnam by joining Japanese technology and the excellent capabilities of Vietnamese staff.

In February 2019, a manufacturing line was completed that is capable of manufacturing head plates indispensable for pressure vessels and performing fabrication, heat treatment, and machining with a vertical precision-milling machine in-house through one-stop production. The convection-type car bottom heat treatment furnace, the exhaust duct, and the stack were designed by Rozai Kogyo and manufactured by RK ENGINEERING, and Vietnamese staff of RK ENGINEERING alone designed and manufactured the LPG tank and the LPG supply system, which are attached structures.

We believe that with these capabilities, we can provide equipment that completely meets customer needs in a wide range of fields.

We, Vietnamese and Japanese employees, will continue to join forces to become a manufacturer that can win the trust of all customers.

| Company name | RK ENGINEERING CO.,LTD. |

|---|---|

| President | SABURO KOBAYASH(I President of NIPPON KYOHAN KOGYO CO.,LTD.) |

| Address 〈Office ・Factory〉 | Land plot CN3.2K,Dinh Vu I.Z, Dong Hai ward , Haiphong City, Vietnam Tel:+84-225-326-0715~8 Fax:+84-225-326-0719 E-Mail:info@rk-eng-vn.com |

| Established | April 14, 2011 |

| Operation started | April 2012 |

| Paid-up Capital | US$5,663,000 |

| Investment ratio | NIPPON KYOHAN KOGYO CO.,LTD. 100% |

| Business | Manufacturing and sale of pressure vessel, head plate, industrial furnace, refractory, burner, etc. |

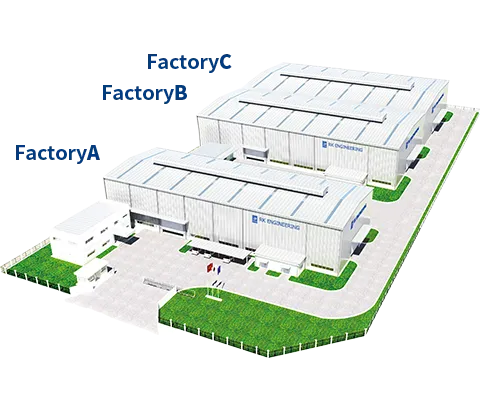

| Site area | 15,000 m2 |

| Factory area | 5,300m2 |

| Employees | 106 |

Equipment introduction

Main facilities

❶Office

❷Machining area

❸1000ton pressing machine

- 1000t W6000 x Daylight 2500

❹SSM (Special Spinning Machine)

- 14t x ⌀ 3000 x Max.Height 3000

❺Canteen

❻Bending roll

❼Open yard rail

❽Hydraulic pressing machine

- 300t

❾Spinning machine

- 22t x ⌀ 800~⌀ 4000

❿Plasma cutting machine

⓫Overhead travelling crane 20t

⓬Convection-type car bottom

- heat treatment furnace

⓭Outside overview

⓮Vertical Precision Milling Machine

List of RK ENGINEERING’s equipment

Click here to see pictures of equipments.

List of RK ENGINEERING’s equipment (As of March 2020)

| Equipment | Capabilities | Quantity |

|---|---|---|

| Convection-type car bottom heat treatment |

Inside dimension(W4000×H4000×L7000) Max.temp.1050℃ Max.weight30t |

1set |

| Hydraulic pressing machine | 1000t W6000×Daylight2500 | 1set |

| Hydraulic pressing machine(with manipulator) | 300t | 1set |

| Spinning machine | 22t×φ800-φ4000 | 1set |

| Special Spinning Machine | 14t×φ3000×Max.Height 3000 | |

| Bending roll | 25t×W2550 | 1set |

| Bending roll | 6t×W2000(Min. φ150) | 1set |

| CNC gas/plasma cutting machine | W2500×L6000 Thickness (SS Max. 60mm, CS Max. 120mm) |

1set |

| Vertical Precision Milling Machine | W2300×H2100×L4000 | 1set |

| Lathe | Max. φ1600、Max.length 3000 | 2sets |

| Band saw machine | Thickness Max. 400mm | 1set |

| Milling machine | Table length 800mm | 2sets |

| Radial drilling machine | 1210L×640H Max. φ32 | 2sets |

| Slotter | Max. φ100mm | 1set |

| Welding positioner | 500kg, 150kg | 3sets |

| Turning rolls | 10t | 6式 |

| Turning rolls | 5t | 3式 |

| Gas cutting machine | 6sets | |

| Plasma cutting machine | Max. 60mm | 1set |

| Submerged arc welding machine | 1000A | 1set |

| MAG welding machine | 350A | 25sets |

| TIG welding machine | 300A | 9sets |

| TIG welding machine (Small-sized) | 200A | 2sets |

| Arc welding machine | 400A | 3sets |

| Arc welding machine (Small-sized) | 200A | 5sets |

| DC arc welding machine | 630A | 2sets |

| TIG Meister | 2sets | |

| Tube end seal automatic welder | 1set | |

| Grinder | 27sets | |

| Beveling machine for Head plate | 1set | |

| Polishing machine (Automatic) | 1set | |

| Polishing machine (Manual) | 13sets | |

| Hydraulic pressing machine (for straightening) | 100t | 2sets |

| Compressor | 15Hp | 2sets |

| Pressure pump | 4sets | |

| PMI(Positive Material Identification)equipment | 1set | |

| Overhead travelling crane | 20t | 2sets |

| Overhead travelling crane | 10/5t | 1set |

| Overhead travelling crane | 10t | 2sets |

| Overhead travelling crane | 5t | 5sets |

| Gantry crane at open yard | 20/5t×22mm | 1set |

| Jib crane | 0.5t | 4sets |

| Forklift | 5t | 1set |

| Welding rod dryer | 100kg | 1set |

| Portable welding rod dryer | 4sets |

Quality control

We are endeavoring to enhance our corporate value through the manufacture of safe products and build relationships that earn us the trust of customers.

-

Quality policy

To satisfy customer requirement on Quality, Cost, Delivery and Safety, we make concered efforts together to take actions to continually improve effectiveness of the quality management system by clarifying the roles and responsibilities and by improving employee's competence.

-

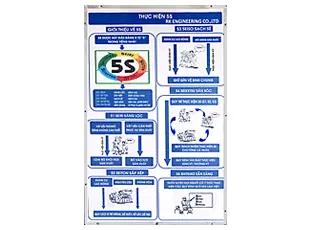

1S + 5S

Improvement activeties

Safety

S1 Seiri (Sorting/Tidiness)

S2 eiton (Setting in order/Orderliness)

S3 Seiso (Shining/Cleanliness)

S4 Seiketsu (Standardize)

S5 Shitsuke (Sustain/Discipline) -

Greeting campaign

We promote a greeting campaign to establish closer internal communication.

-

Safety management

We strive to manage the safety of our employees and products.

Acquired qualifications

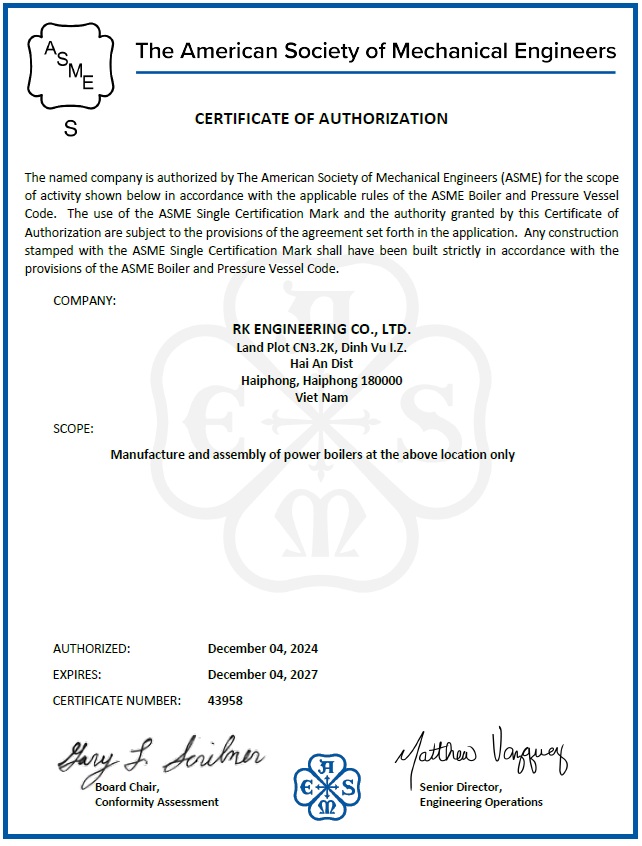

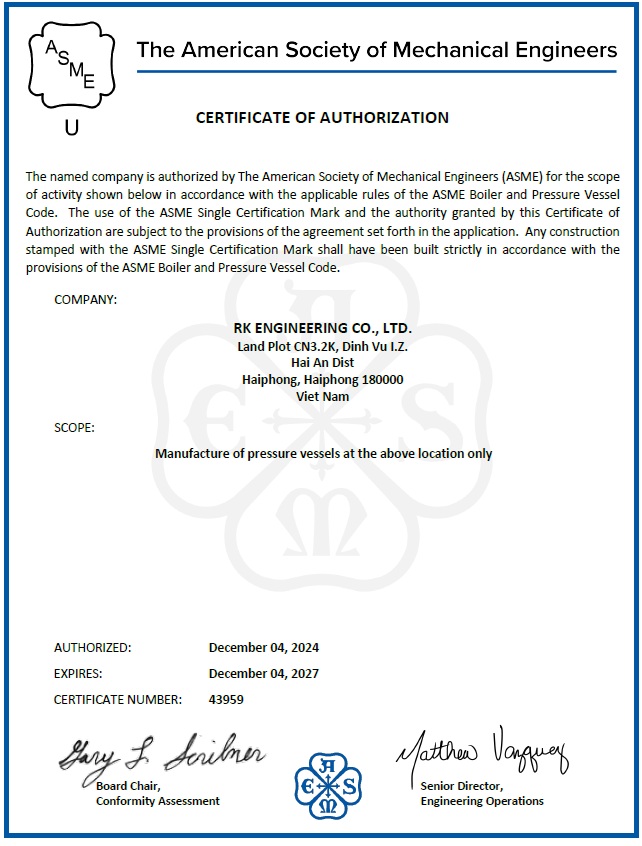

On December 4, 2012, RK ENGINEERING received a qualification certificate of ASME, which is the manufacturing and engineering standard for the manufacture of power boilers and pressure vessels. RK ENGINEERING was the first Japanese company operating in Vietnam to acquire the ASME qualification for the manufacture of power boilers and pressure vessels, and is contributing to manufacturing power generation, chemical, and food plant equipment in Southeast Asia, including Vietnam, and China.

ASME stands for The American Society of Mechanical Engineers. Of the standards developed by ASME, the ASME Boiler and Pressure Vessel Code specifies the safety rules for managing designs and inspections of pressure vessels and equipment for nuclear power plants.

ASME certified company

-

The first meeting for ASME

-

The second meeting for ASME

-

The third meeting for ASME

-

Demo-fabrication for ASME

-

Final survey for ASME(Document)

-

Final survey for ASME(Factory)

Catalog download(Japanese)

Catalog download(Japanese) Catalog download(English)

Catalog download(English)