The strengths of Nippon Kyohan Kogyo Co., Ltd.

Advanced processing technology and speedy response

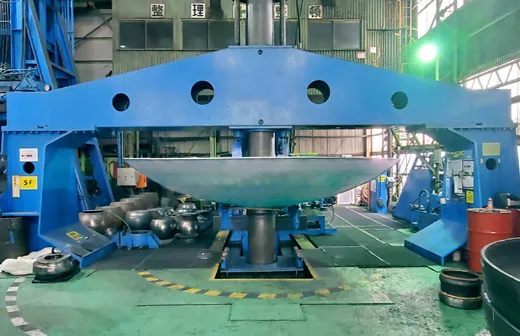

Nippon Kyohan Kogyo manufactures products at five business bases in Japan through region-based sales activities and an integrated production system encompassing steps from design to processing, inspections, and delivery. Thus, we can respond to customer needs flexibly and speedily. We deliver high-quality products by making the best use of a 9,000-ton press, which is one of the largest presses in the industry, a large-size spinning machine, a special spinning machine, and other equipment and our unique technologies centered on cold working process technology.

-

- 01 High quality

- All the members of the company worked hard together to strengthen quality control, and it became the first company in the head plate industry to acquire ISO 9001 certification. As a pioneer specialized in the manufacture and processing of head plates, we have enhanced our unique technologies, mainly the cold working process technology that does not impose burdens on materials.

-

- 02 Ability to respond

- We strive to improve customer satisfaction by giving top priority to customer requests, such as delivery dates and costs. Our sales staff help customers solve their issues from each customer’s perspective. It is our pleasure to satisfy customers.

-

- 03 Ability to make proposals

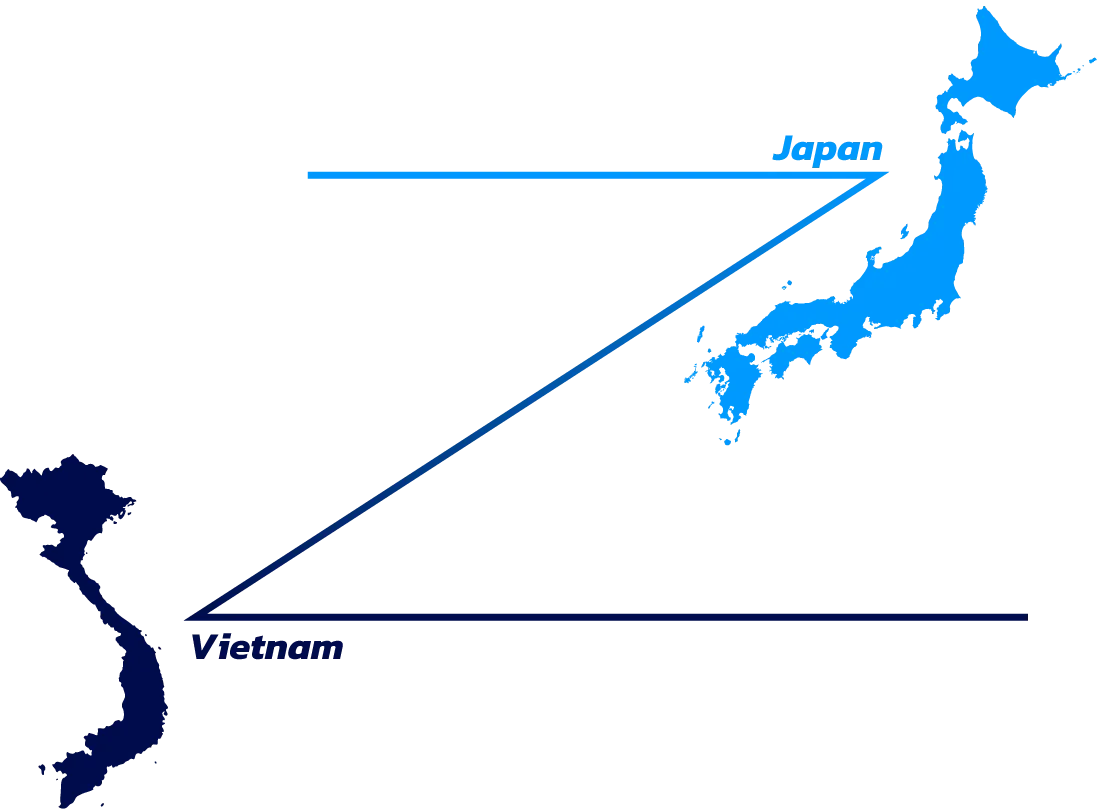

- For example, do you have any problem with the delivery date, cost, capacity, etc. of the manufacture of pressure vessels? Utilizing the quality and experience we have accumulated through the manufacture of head plates for pressure vessels, we can serve as a bridge between Japan and Vietnam and propose various solutions, including the placement of orders with overseas companies.

What Nippon Kyohan Kogyo Co., Ltd. is good at

Nippon Kyohan Kogyo can deal with a wide range of customer needs for head plate processing with flexibility. In addition to head plates, we can produce can bodies in-house through a one-stop production system. Our overseas group affiliate (RK ENGINEERING) produces can bodies and undertakes canning operations in compliance with ASME standards and other laws and regulations. For inquiries, please feel free to contact the Overseas Sales dept. of Nippon Kyohan Kogyo Co., Ltd., which responds to requests, including international business transactions.

-

Design and acceptance of orders

Please contact the Sales Department of Nippon Kyohan Kogyo. The Overseas Sales dept. of Nippon Kyohan Kogyo will deal with even products manufactured overseas.

-

Manufacture and delivery of head plates

The factories of Nippon Kyohan Kogyo in Japan manufacture head plates.

-

-

Manufacture and delivery of can bodies

The entire group, including the Vietnamese factory of the overseas group affiliate RK ENGINEERING, can manufacture up to can bodies with manufacturing capabilities supported by equipment and a flexible response.

Quick response system that can solve problems unresolvable with existing products

Nippon Kyohan Kogyo, which has its own designers, offers designs that meet all customer requirements. Our designers will attend meetings in order to offer appropriate designs. Since we can manufacture products based on these designs, we can “create new products that have never been manufactured.” We propose the manufacture of industrial containers that can satisfy even customers who have trouble coming to terms with standards and conditions.

Cold working process technology that Nippon Kyohan Kogyo has developed to the extreme

We form various types of head plates with inner diameters of 200 to 3,200 mm (50-mm pitch for inner diameters of up to 2,000 mm and 100-mm pitch for inner diameters of more than 2,000 mm) and plate thicknesses of up to 28 mm by cold forming using the fully automatic press exclusively for head plates developed in-house.

The cold press forming method, which has realized the standardization of head plates complying with JIS standards, achieves stable quality and extremely high productivity.

We can also manufacture head plates exceeding 13 meters in length.

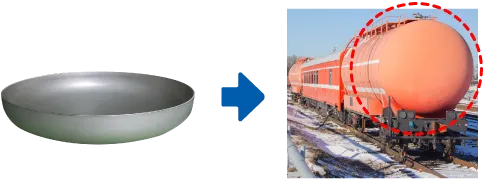

What is a head plate?

A head plate is a hemispherical member and an industrial component attached to both ends of various types of industrial equipment, tanks, and pressure vessels. Head plates are widely used for industrial pressure vessels and are indispensable products for equipment that is an integral part of our daily lives, such as plants, food processing, chemical refinement, and storage facilities.

What is the origin of the name of head plates?

What is a head plate?

A head plate is a hemispherical member resembling a “kagami-mochi” (round rice cake) and is widely used for the end faces of a wide variety of industrial equipment, tanks, pressure vessels, etc.

- There are various theories about the origin of the name.

-

- ・Theory that the lid plate of a wooden barrel filled with sake was called a head plate

- ・Theory that the name followed the shape of kagami-mochi

Other countries refer to head plates using the following words:

- USA: Head plate

- UK: End plate

- China: 封頭

- Taiwan: 端板

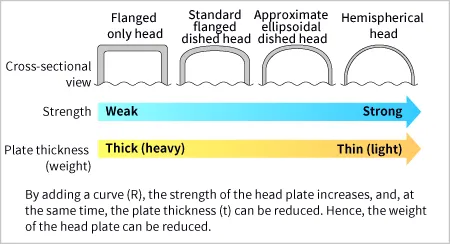

Reasons for being round

A head plate is attached to disperse pressure and prevent stress concentration. Providing the shape of a head plate with a curve (R) increases its strength. In addition, the design plate thickness can be made thinner than a flat plate, which contributes to reducing material costs and equipment weight.

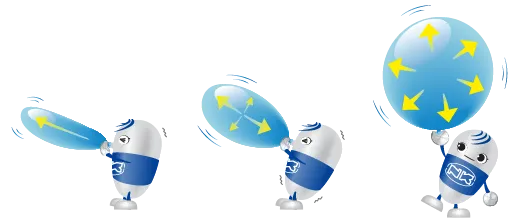

- Think of a balloon.

- Balloons vary in shape. As they are blown up, balloons of various shapes all become spherical. When the inner pressure spreads and stabilizes, a sphere is the optimum shape. This also applies to metal. To withstand internal or external pressures, the part must have the shape of a sphere.

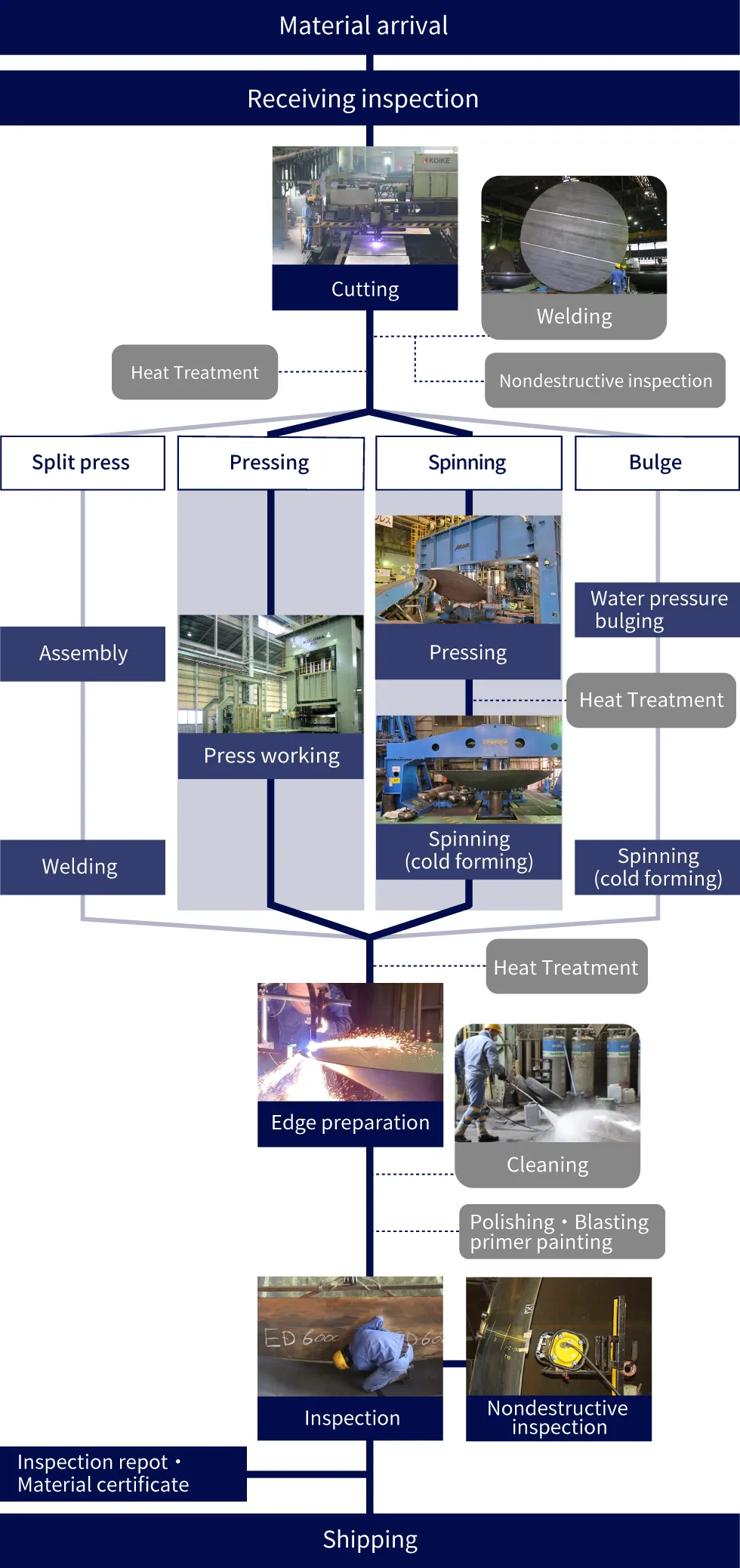

Head plate manufacturing process

Shown below is a general process of manufacturing head plates.

We manufacture head plates with optimum processing technology according to the inner diameter, plate thickness, shape, or application.

Each step of pressing, spinning, and bulging is supported by the hot working process or cold working process. The cold working process, which does not apply heat, requires more advanced technology than the hot working process, but can offer products with stable and high quality. Nippon Kyohan Kogyo can manufacture head plates with plate thicknesses of up to 28 mm using the cold working process.

Our products are selected by customers in a wide range of industries.

- Plants

- Gas plants, waste oil plants, light buoys essential for the safety of ships, can bodies for spray-type cleaning equipment and ultrasonic cleaning equipment, etc.

-

- Chemical refinement

- Chemical plants, agitation containers, medical appliance plants, high-concentration purified water tanks, can bodies for autoclave sterilizers, etc.

-

- Food processing

- Beer storage tanks, small-size brewing craft beer plants, shochu (distilled beverage) brewing tanks, heating steam cans, drinking water production, can bodies for high-pressure sterilizers for mushroom cultivation, etc.

-

- Storage equipment, etc.

- Gasoline storage at gas stations, boilers, underground storage tanks at oil stations, tank trucks, railway tank trucks, etc.

-

Contact Please feel free to contact us even about products that other manufacturers refused to produce.

Details, such as manufacturing methods, materials, processes, and the required number of days for manufacture, and products each manufacturer can deal with are different.

Please feel free to contact Nippon Kyohan Kogyo even if you have not agreed with another company on the conditions of a product you are considering or of a current project you want to review. We can propose the best possible measures that combine the technical capabilities we have accumulated as a manufacturer specialized in head plates and the production of cans by our overseas group affiliate via the Overseas Sales dept.