One Stop

Production

Global Mind

with

Japanese Quality

One-stop production of industrial pressure vessels

At RK ENGINEERING, a Vietnam-based affiliate, we can meet the needs of domestic and overseas plant manufacturers through a one-stop production system by utilizing the head plate manufacturing technology we have accumulated in Japan. We sell a wide variety of pressure vessels and food- and medical product-related equipment in Japan and around the world.

Strengths

We meet customer needs with Japanese quality and a one-stop production system.

RK ENGINEERING has ISO certification for management and ASME certification for products, and fabricates and manufactures all equipment and products, up to large-size fabrication. In addition, we offer Japanese quality, and our Overseas Division in Japan places orders with the Vietnam Factory for products while maintaining communication with customers. We help customers in overseas procurement without risks.

-

Made by japan Japanese quality

We have acquired ISO 9001 certification and ASME S and U Stamps for our manufacturing system. For Japanese company customers, RK ENGINEERING’s Overseas Division in Japan serves as the contact with the Vietnam Factory while maintaining communication with them, so that they can place orders without anxiety. There is no need to worry about communication problems due to the language barrier or the receipt of a completely different product than you expected.

-

One-stop Production Ability to respond

We realize one-stop production because we have all the necessary equipment and personnel in place and can deal with all operations of head plate production, machining, heat treatment, and polishing in-house. Completing all manufacturing operations in one place also ensures quality and strict observance of delivery dates. In addition, we have fabricated cans with a maximum diameter of 4,000 mm and a maximum length of 20,000 mm through integrated manufacture, and have dealt with lifting loads up to 40 tons. Even head plates exceeding this size can be manufactured and shipped by separating them into pieces.

-

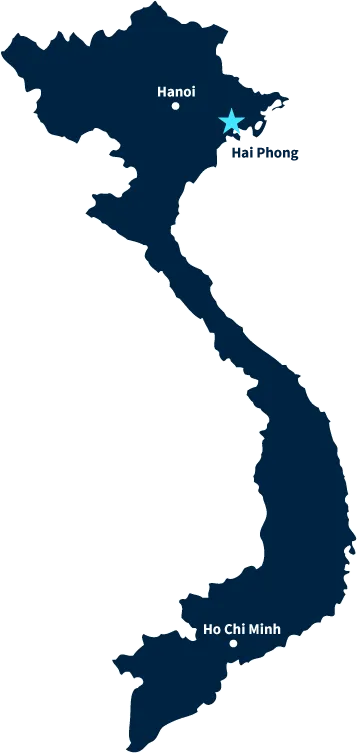

Import & Export

RK ENGINEERING is located near the Port of Hai Phong and can ship products directly from there. It takes about two to three weeks to transport products to Japan by sea, and about two hours to reach Hai Phong from Hanoi, where Noi Bai International Airport is located for air services. In addition, RK ENGINEERING’s Vietnam Factory is an export processing enterprise (EPE) and therefore exempt from export duties and facilitates smooth customs clearance compared with local companies. We have the upper hand over other companies both in cost and in delivery performance.

-

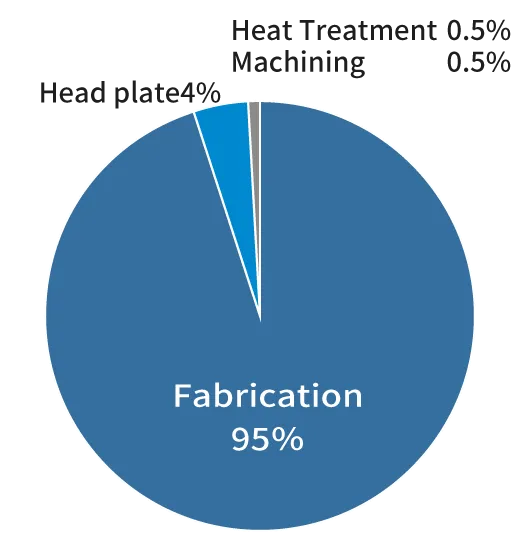

Orders for Fabrication account for 95% of our business sales.

-

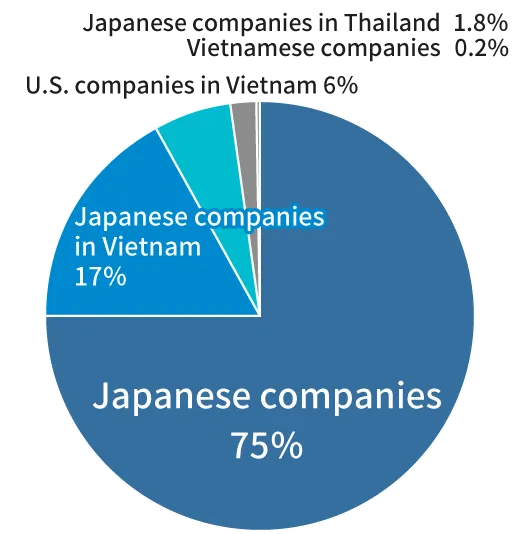

Deliveries to Japanese companies account for 75% of our business transactions, and our services are selected by customers whose needs and specifications could not be fulfilled by overseas local companies.

-

Japanese engineers provide technical guidance for developing and training Vietnamese staff, who realize high quality.

-

A person in charge of quality control is assigned to each manufacturing project and manages the entire process from the receipt of materials to shipment.

One Stop Production

We can deal with four types of services: orders for all operations of fabrication, orders for only machining, orders for only heat treatment, and orders for only the manufacture of head plates. Accurate products are needed inside and outside Vietnam, and we have received many inquiries for only partial processing.

-

- Fabrication

- We manufacture a wide variety fabrication products, mainly stainless steel (SUS) fabrication, as well as carbon steel fabrication. We can offer large-size fabrication products measuring up to 4,000 mm in diameter and up to 20,000 mm in length, and have a maximum monthly production capacity of about 60 tons. SUS products are susceptible to scratches, rust, etc. and need to be stored with care. Besides, we concentrate efforts on quality control and education.

-

- Head plate

- Our factory also has diverse types of equipment, such as a hydraulic pressing machine with manipulator and a spinning machine. We manufacture a wide variety of head plates used for chemical, pharmaceutical, food, and other plant facilities.

-

- Machining

- With a new-generation vertical precision milling machine, which is capable of performing simultaneous multi-face machining, we can finish complicated processes from the top and side faces at a time. We can meet customers’ requests for the machining of pressure vessels and structures with the latest machining technologies.

-

- Heat Treatment

- Heat treatment processing technology for improving the completeness of metallic materials by increasing the strength, elongation, and toughness, and enhancing the functionality of mechanical parts and structures. The factory has a convection-type car bottom heat treatment furnace, which is among the largest of its size and with the highest heat treatment temperatures and the largest treatment capabilities, and performs heat treatment services.

DEEP C Industrial Park There are three biggest reasons why RK ENGINEERING chose the Deep-C Industrial Park in Hai Phong.

- Regional characteristics

- Vietnam is located in the center of Southeast Asian countries and China and it has remarkable economic development.

Hai Phong City is located 100km east of Hanoi which is the capital city and it is a logistics center having an international trading port. - Site location

- The Deep-C Industrial Park is adjacent to Dinh Buo Port, Hai Phong's international trading port, and it is very suitable for loading raw materials and shipping large-scale products by sea.

They also completed the construction of Lac Yen Port to meet the increasing demand for containers.

What's more it has a highway CT.04 between Hanoi and Hai Phong other than sea transportation, it takes 1 hour and 45 minutes by car to Hanoi, and it also has Cat Bi International Airport connecting central and southern Vietnam from it. - Technical capabilities

- Haiphong is historically well known for the shipping industry, and there are many factories engaged in cutting, bending, and welding iron because shipping industry has its own wide skirts.

Therefore, we can hire highly skilled employees, and also find many companies who can help us with our production.

Catalog Download

-

JAPANESE catalog

(PDF format:3.95 MB)

Catalog download(Japanese) -

ENGLISH catalog

(PDF format:3.53 MB)

Catalog download(English)

Catalog download(Japanese)

Catalog download(Japanese) Catalog download(English)

Catalog download(English)